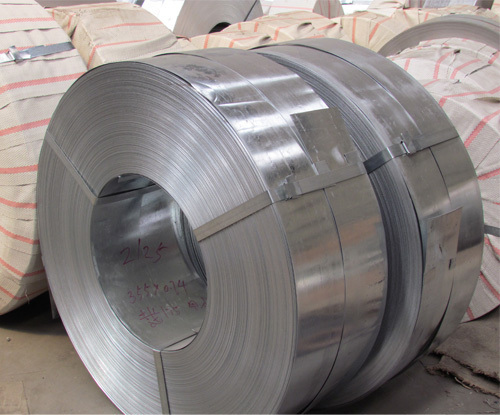

235 warara ígwè

Nkọwa dị mkpirikpi:

A na-enyekarị nchara nchara na eriri igwe, nke nwere uru nke nha nha dị elu, mma elu dị mma, nhazi dị mfe, nchekwa ihe na ihe ndị ọzọ.Otu ihe ahụ dị ka efere nchara, a na-ekewa nchara nchara n'ime nchara nkịtị na nke dị elu dị elu dịka ihe eji eme ihe;Dị ka usoro nhazi ahụ si dị, a na-ekewa ya na eriri ọkụ na-ekpo ọkụ na oyi na-ekpo ọkụ.

Usoro mmepụta nke mpempe akwụkwọ oyi na-adịkarị ka ndị a: pickling → rolling → nhazi mmanu → annealing → leveling → shearing → packaging.

Usoro mgbawa oyi akpọrepu: pickling - rolling - annealing - synchronous lubrication of rolling size - antirust oil - nhazi ọkwa na nha - polishing - nkwakọ

Usoro ikpo ọkụ na-ekpo ọkụ: ọkụ ọkụ - igwe dephosphorization - igwe igwe igwe - igwe dephosphoriization - igwe ihe na-emecha - ngwa nyocha nke elu - oyi akwa - coiler - baler - igwe akara - igwe na-atụgharị ngwaahịa slab

Usoro mmepụta ihe na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ: nke mbụ, bulite okpomọkụ na ọkụ ọkụ na okpomọkụ nke achọrọ, wee banye na igwe dephosphorization nke na-agbagharị agbagharị site na tebụl rola iji na-emeso ọnụ ọgụgụ oxide nke ígwè ahụ na-emepụta site na slab, wee banye na igwe na-agbagharị agbagharị iji tụgharịa. obosara na ọkpụrụkpụ nke warara, wee bufee ya site na tebụl roller gaa na igwe dephosphorization na-emecha iji na-emeso ọnụ ọgụgụ ígwè oxide nke a na-emepụta n'elu nke warara ahụ, Tinye ihe na-agbagharị agbagharị maka ntụgharị nke ọma nke ọkpụrụkpụ na obosara. nke warara ígwè.Mgbe tebụl rola na-achịkwa nke ọma n'elu okpomọkụ nke nchara nchara site na oyi akwa oyi tupu ịgbakọ, ọ na-abanye na coiler ka ọ bụrụ eriri igwe.N'ikpeazụ, a na-ejikọta ya, fesa ya ma ziga ya n'ụlọ nkwakọba ihe maka nchekwa na nkwakọ ngwaahịa.